Conductors

Due to its high conductivity, copper is the most commonly utilized conductor material; however, conductor material can vary based upon specific application requirements. Examples of alternative materials include:

- Oxygen Free Copper – Improved resistance to oxidation

- Aluminum – Excellent conductivity to weight ratio; commonly used in the aerospace industry

- Copper Alloy – Provide high strength to withstand the effects of repeated flexing and other mechanical abuse

- Copper Clad Steel – Typically used for high frequency applications that require improved mechanical properties

- Copper Clad Aluminum – Cost effective replacement for solid copper in high frequency power applications

- Resistance Wire – Used in a wide variety of applications from thermocouples to high resistance leads

- Magnet Wire – See our webpage on Litz Wire for more information

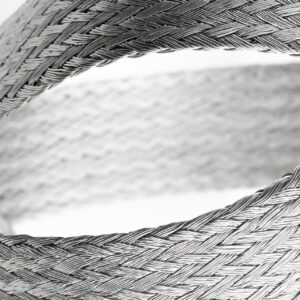

Plating

A variety of conductor plating options are available to meet specific temperature, corrosion, termination and aesthetic requirements. Our in-house tin and silver plating capabilities ensure that New England Wire can manufacture or purchase wire to whatever plating thickness that may be required.

- Tin – A cost effective solderable coating that is moderately oxidation resistant

- Silver – Excellent soldering characteristics and electrical conductivity

- Nickel – Extremely high temperature rating (450°C)

- Gold Plated Nickel Flashed – Gold plated to minimize contact resistance and nickel flashed to prevent gold-copper alloying

- Platinum – Exceptional chemical resistance

- Tinned Lead – Exceptional solderability, rarely used outside of military applications

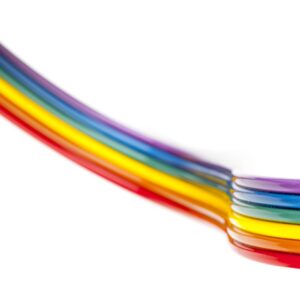

Stranding

Flexible Interconnects can be made from single end conductor strand sizes between 30 AWG – 52 AWG, with non-standard single end sizes available as required.

Size

Interconnects can be made to any equivalent gauge size or to match specific area (CMA, mm²) and can range from 44 AWG to 500 MCM conductors. They can be designed to match a target insulation diameter, a target conductor diameter or target resistance.

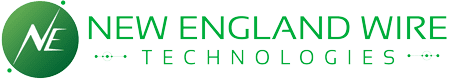

Insulation

Custom flexible interconnects may be insulated with any of the insulation materials offered by New England Wire Technologies and are typically chosen based upon application requirement. Materials offering superior flexibility are most commonly utilized; however, materials offering abrasion, chemical and temperature resistance are also available.

Design Considerations for Custom Flexible Interconnects

- High Temperature

- Conductors

- Silver Plated Copper – UL Rated to 200°C

- Nickel Plated Copper – Rated up to 450°C

- Insulation Materials

- FEP (Fluoropolymer) – 200°C

- PFA (Fluoropolymer) – 250°C

- Silicone Rubber – 200°C

- Conductors

- Low Temperature

- Fluoropolymer – Cryogenic

- Silicone Rubber – Cryogenic

- Polyurethane -50°C

- Chemical Resistance

- Fluoropolymer

- Polyester

- Nylon

- Voltage

- Fluoropolymer – Excellent Dielectric Strength

- Silicone Rubber – Resistant to Corona breakdown in high voltage AC applications

- Low Capacitance

- Fluoropolymer (2.03 – 2.08 Dielectric Constant)

- Polyethylene (2.28 – 2.32 Dielectric Constant)

- Flexibility

- PVC – Good Flexibility, modest cut through and tear resistance

- Silicone Rubber – Excellent flexibility, poor mechanical properties

- Thermoplastic Elastomers – Improved flexibility over PVC, with better mechanical properties than Silicone