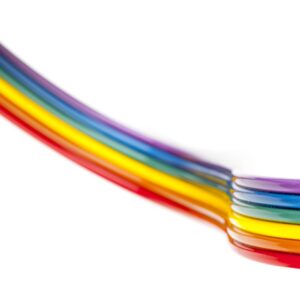

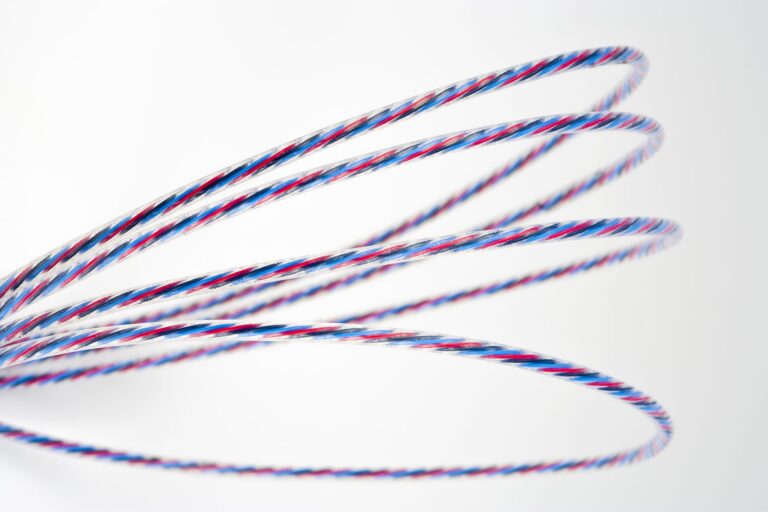

Balanced Pair (Twinax)

Twisted pairs have been used for decades as a low cost means to reduce interference between signal wires and surrounding electronics. When an electromagnetic field encounters an electrical conductor a voltage is induced in the wire. In digital applications induced voltages will interfere with data transfer and result in lower performance or a complete loss of signal integrity.

Balanced circuits

Balanced circuits were developed as a means to reduce the effects of EMI on signal cables. In traditional wire, the signal is a function of a voltage in a single line, in balanced circuits a signal is a function of the voltage differential between two signal lines. When a balanced circuit is placed in an electromagnetic field, the voltage is generated in both lines, effectively canceling each other out.

Twisted Pair

To maintain the effectiveness of a balanced circuit, the signal lines have to control two parameters. First, each line has to have comparable impedance, which ensures that an electrical field will generate the same voltage in each line. Second, each line has to be subjected to the field in approximately the same way. Twisting the lines together helps control both of these parameters, the transposition of the wires ensures that each leg is exposed to EMI in the same approximate way, and helps consistently maintain the parameters that effect impedance.

Common Uses

Twisted pairs are used in a variety of consumer goods, Category cable, USB and HDMI all employ twisted pairs for signal lines.

Advantages

- Reduced Voltage – Less susceptible to EMI, twisted pairs can use lower operating voltages which can both improve efficiency and data speeds

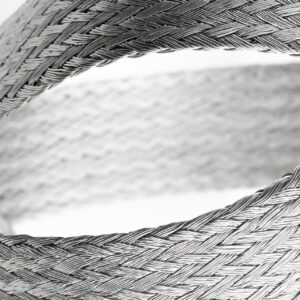

- Improved Flexibility – Since coaxes require large dielectric layers and metallic shielding, cabled twisted pairs can offer significant increases in flexibility.

- Lower Cost – Requiring fewer operations and less materials to manufacture, twisted pairs are an excellent lower cost alternative to coaxes.

New England Wire uses planetary cabling equipment for multi-conductor cables; this equipment ensures reliable and consistent transposition for twisted pairs. We also use inline electrical monitoring to ensure high quality and consistent electrical performance on all our products.